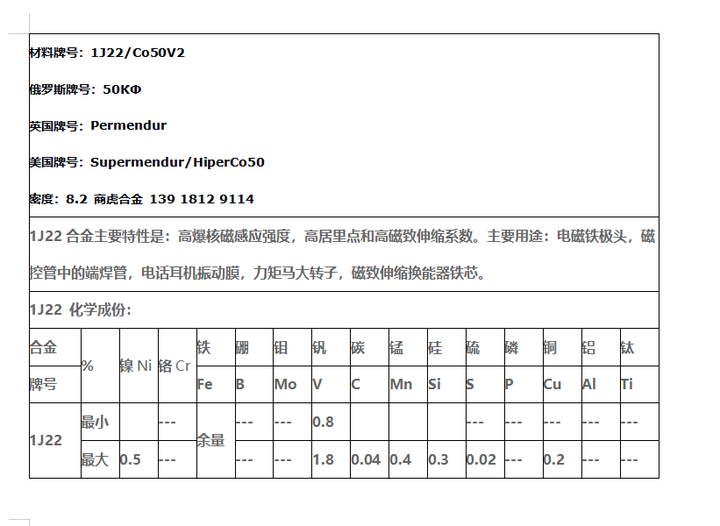

1j221J22 is an iron-cobalt-vanadium soft magnetic alloy with high saturation magnetic induction intensity. Among the existing soft magnetic materials, the alloy has the highest saturation magnetic induction intensity (2.4T), a high Curie point (980°C), and the largest saturation magnetostriction coefficient ( 60~100×10-6). Due to the high saturation magnetic induction intensity, when making motors of the same power, the volume can be greatly reduced, and when making electromagnets, a large suction force can be generated under the same cross-sectional area.

Processing technology of use scene(1) Heat treatmentCold-rolled strip sample: heat up to 850~900℃ with the furnace, keep warm for 3~6h, cool down to 750℃ at a speed of 50℃/h, then cool to 300℃ at a speed of 180~240℃/h, and release the furnace, annealing medium It is hydrogen with a dew point not higher than -40°C.

(2) Samples taken from forging billets:

Heat up to 1100℃±20℃ with the furnace, keep for 3~6h, cool down to 850℃ at 50~100℃/h, keep for 3h, then cool to 700℃ at 30℃/h, then cool at 200℃/h After cooling to 300℃, the annealing medium is hydrogen with a dew point not higher than -40℃.

(3)For materials requiring higher magnetic induction, lower coercivity, and higher squareness ratio under lower magnetic fields:

Heat up to 850℃±10℃ with the furnace, keep for 4h, cool to 750℃ at 50℃/h, keep for 3h, then cool to 300℃ at 200℃/h, and release the furnace, add 1240~ 1600A/m DC magnetic field, annealing medium is hydrogen with dew point not higher than -40℃.

Application fieldIt is suitable for light weight and small size aviation and aerospace electrical components, such as microelectronic rotors, electromagnet poles, relays, transducers, etc.