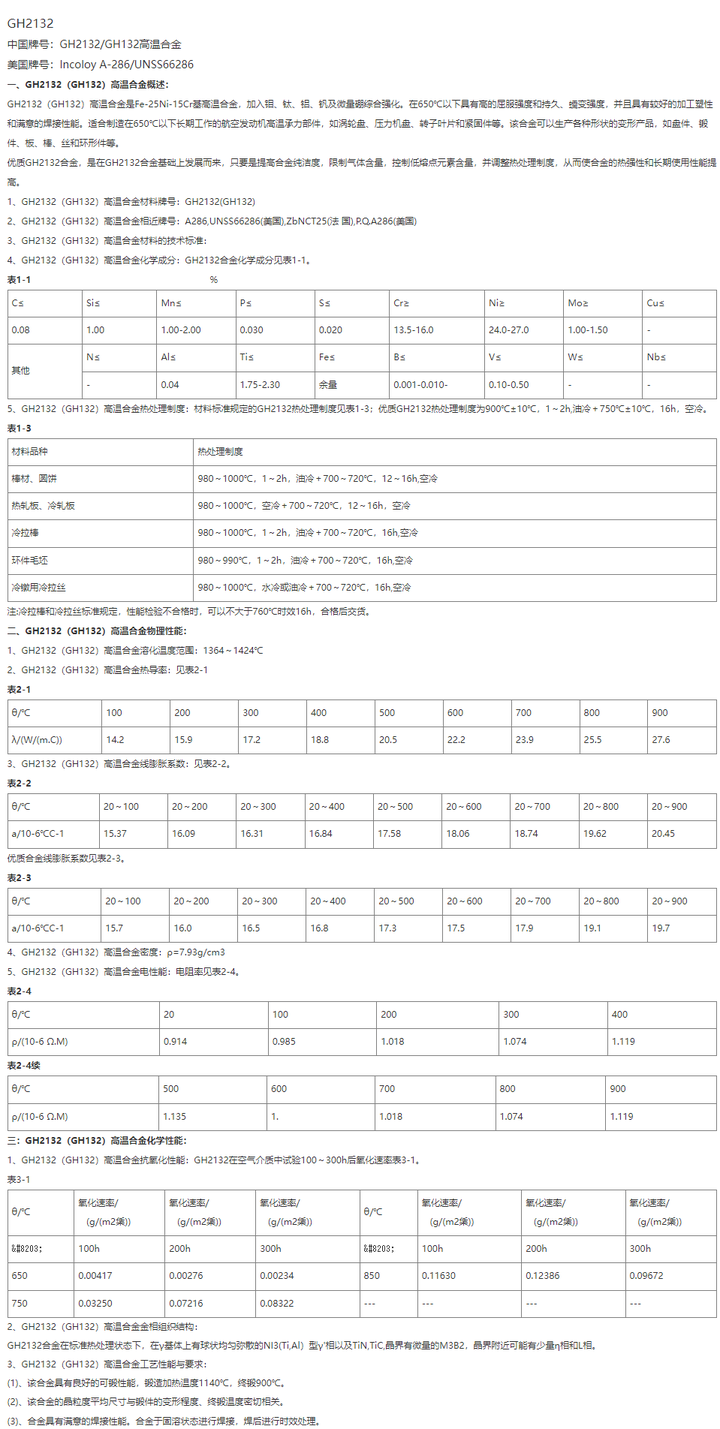

Strip, plate, round bar, flat bar, forging stock, hexagon and wire.

2.LIMITING CHEMICALCOMPOSITION,% Ni ..... 24.0 – 27.0

Cr......13.5 – 16.0

Fe........... Balance

Ti ......1.90 – 2.35

Mo.........1.0 – 1.5

V........0.10 – 0.50

C..........0.08 max.

Mn......... 2.0 max.

Si........... 1.0 max.

Al .........0.35 max.

S....... 0.030 max.

B.... 0.001 – 0.01

3.PHYSICAL CONSTANTS AND THERMAL PROPERTIESDensity, Ib/in3 ........................................................................0.287

g/cm3 ..........................................................................7.94

Melting Range, °F ..................................................2500 – 2600

°C ..................................................1370 – 1430

Specific Heat, Btu/lb•°F ....................................................0.100

J/kg•°C........................................................... 419

Permeability at 200 Oersted (15.9 kA/m)....................1.007

Coefficient of Expansion, 10-6 in/in•°F (µm/m•°C)

70 - 200°F (21- 93°C).................. 9.09 (16.4)

70 - 800°F (21- 427°C)................9.61 (17.3)

70 -1400°F (21-760°C)................9.67 (17.4)

Thermal ConductivityA , Btu • in/ft2•h•°F.............................88

W/m •°C........................................ 12.7

Electrical ResistivityA , ohm • circ mil/ft............................. 547

µΩ•m ............................................0.910

Young's ModulusA , 106 psi ................................................... 29.1

GPa.......................................................... 201

HardnessA , HRC ..........................................................................31

A Room temperature, as annealed.